Sourcing Plastic Stool and Cap Molds from China

Complete Guide: Sourcing Plastic Stool and Cap Molds from China

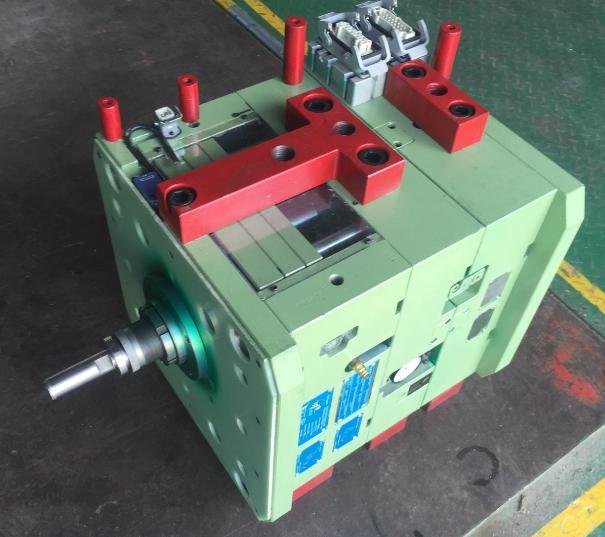

Understanding China's Mold Manufacturing Excellence

China's plastic injection molding industry has transformed dramatically over the past decade. When looking to source durable plastic stool molds for your manufacturing needs or seeking precision cap and closure tooling solutions, understanding the Chinese market becomes essential for success.

Essential Quality Parameters for Mold Selection

Critical Specifications for Stool Molds

Quality stool mold production requires careful attention to several key factors:

- Material selection and durability requirements *** Surface finish specifications ** Load-bearing capacity considerations

- Anti-slip texture integration ***** Assembly mechanism design

Precision Requirements for Cap Molds

Cap mold manufacturing demands exceptional accuracy:

- Thread precision specifications *** Sealing mechanism design ** Material flow optimization **** Ejection system requirements

- Multi-cavity configurations

Cost Analysis and ROI Considerations

| Mold Type | Investment Range | Production Capacity | Maintenance Level | Lifetime |

|---|---|---|---|---|

| Stool Molds | $8,000-$25,000 | 100,000/month | Medium | 5-7 years |

| Cap Molds | $15,000-$50,000 | 500,000/month | High | 3-5 years |

Supplier Selection Criteria

Initial Screening Process

Consider these crucial factors:

- Manufacturing capabilities *** Quality certification status

- Previous project portfolio **** Technical expertise level ** Production capacity *** Export experience

Advanced Verification Steps

Thorough verification includes:

- Factory audit results *** Sample quality assessment **** Financial stability checks ** Industry reputation

- Communication efficiency

Technical Specifications and Design Requirements

Engineering Considerations

Key technical aspects include:

- Material flow analysis *** Cooling system design ** Gate location optimization **** Venting requirements

- Surface finish specifications

Production Timeline Management

Standard Production Phases

Typical timeline breakdown:

- Design approval (1-2 weeks) *** Mold flow analysis (1 week) ** Initial manufacturing (3-4 weeks)

- Testing phase (2 weeks) ***** Modifications (1-2 weeks)

Quality Control Protocols

Pre-Production Quality Measures

Essential quality checks include:

- Design review meetings *** Material testing procedures

- Dimensional verification **** Surface finish inspection ** Functionality testing

Production Monitoring Systems

Implement these monitoring steps:

- First article inspection *** Regular quality audits **** Process parameter monitoring ** Statistical quality control

- Tool wear assessment

Contract Negotiation Strategies

Key Contract Elements

Critical components to address:

- Payment terms structure *** Quality guarantee provisions ** Delivery timeline commitments

- Intellectual property protection ***** After-sales service terms

Logistics and Shipping Considerations

Documentation Requirements

Essential paperwork includes:

- Commercial invoice details *** Packing list specifications

- Bill of lading requirements **** Quality certification documents ** Export license verification

Maintenance and After-Sales Support

Regular Maintenance Schedule

Implement these maintenance practices:

- Cleaning protocols *** Wear inspection routines ** Cooling system maintenance **** Surface treatment touch-ups

- Alignment checks

What's Your Reaction?