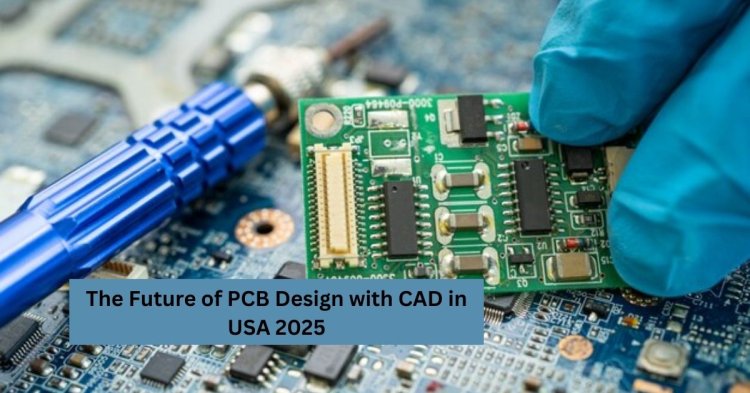

The Future of PCB Design with CAD in USA 2025

Explore the future of PCB design with CAD in the USA by 2025, including trends, innovations, and the role of advanced technologies in shaping the industry

Printed Circuit Boards (PCBs) are the backbone of modern electronics, found in everything from consumer devices to advanced medical equipment and automotive systems. As technology evolves, so too does the process of designing PCBs, particularly with the integration of Computer-Aided Design (CAD) tools. The future of PCB design in the USA looks set to be shaped by innovative advancements in CAD technology. With 2025 just around the corner, understanding these trends and how they will impact the electronics industry is crucial for engineers, manufacturers, and developers. This article explores the key trends that will influence the future of PCB design, how CAD tools are evolving, and what the future holds for PCB design in the USA.

The Role of CAD in PCB Design

CAD software has revolutionized the way PCB designers work. Before the advent of CAD, PCB designs were manually drafted, leading to slower, error-prone processes. With CAD tools, designers can create intricate layouts, test components, and simulate electrical performance with ease. This has not only sped up the design process but also increased the precision and reliability of PCBs.

In addition to traditional PCB design, many businesses are turning to 3D CAD services for more complex or detailed design requirements. These services provide specialized expertise in creating detailed 3D models of PCB layouts, which are essential for precise visualization and testing. With CAD services, engineers can view the design from multiple angles and simulate real-world conditions, improving accuracy and reducing potential errors.

Additionally, CAD Drawing services are increasingly utilized to enhance design accuracy. These services are perfect for businesses that require highly detailed drawings that support the intricate specifications of a PCB. By outsourcing the drawing aspect to professionals, companies can focus on the higher-level design and optimization processes.

The use of CAD in PCB design allows for the visualization of complex layouts, including the integration of multi-layer boards, tiny components, and intricate routing paths. As electronic devices become more compact and powerful, the demand for high-density interconnect (HDI) boards, flexible PCBs, and advanced designs continues to grow. 3D CAD services are increasingly being used to streamline the design process, ensuring that every aspect of a PCB is optimized for performance.

Key Trends Shaping PCB Design in 2025

-

Advanced PCB Materials and Innovations

The future of PCB design will see a shift towards advanced materials that improve performance and durability. As electronic devices become smaller, faster, and more efficient, designers need to use materials that can handle high-speed signals and prevent thermal issues. CAD tools will evolve to integrate these advanced materials, making it easier for engineers to select the right material for their designs and simulate how these materials will behave under different conditions.

For intricate designs, 3D services will be crucial in providing highly detailed simulations of how these materials interact within the PCB. These services will help ensure that the material choice complements the overall design, improving both functionality and durability.

-

Miniaturization and High-Density Interconnects (HDI)

Miniaturization is one of the most significant trends in PCB design. With smaller devices, there is an increasing demand for smaller, more compact PCBs that still maintain high functionality. High-Density Interconnect (HDI) PCBs allow for more components to fit into smaller spaces, offering high-performance capabilities in compact formats. CAD Drawing services can play a key role in supporting HDI designs, offering detailed drawings that ensure accuracy and precision in component placement.

CAD tools are being designed to better support HDI design, providing more advanced routing capabilities, better layer management, and higher precision. In 2025, the push for miniaturization will continue, and 3D CAD will be essential in making these designs a reality.

-

Flexible and Rigid-Flex PCBs

The use of flexible and rigid-flex PCBs has grown significantly, especially in industries such as consumer electronics, medical devices, and automotive applications. These PCBs are lightweight, adaptable, and can be molded into various shapes and sizes. CAD Drawing services are essential for designing these PCBs accurately, as they require specialized expertise in handling flexible materials and multi-layer structures.

CAD software has made it easier to design flexible PCBs, allowing for simulations that predict how these boards will bend, flex, and perform under different conditions. In 2025, the demand for flexible PCBs is expected to continue to rise, and 3D CAD will play a pivotal role in helping designers create these innovative solutions.

-

Automated Design Tools and Artificial Intelligence (AI)

Artificial intelligence (AI) is starting to play a significant role in PCB design, and this trend will only accelerate in 2025. AI-powered CAD tools are already being developed to assist designers in automating repetitive tasks such as component placement, routing, and error-checking. These tools will not only reduce the time it takes to create designs but also improve the overall quality of the final product by minimizing human error.

AI can also be used for predictive design, where the software suggests optimized layouts based on historical data and simulations, helping designers achieve the most efficient and cost-effective solutions. For businesses that need more advanced designs, 3D CAD services will offer additional support by providing expert design reviews and customizations.

-

3D PCB Design and Simulation

In recent years, 3D PCB design has gained popularity as it allows designers to visualize and interact with their designs in three dimensions. This can significantly enhance the design process, as it provides a more accurate representation of how the final product will look and behave. With 3D CAD tools, designers can simulate signal integrity, thermal performance, and mechanical stress, allowing for more comprehensive testing before production. In 2025, 3D CAD services will be a standard practice, and designers will increasingly rely on them to develop optimized, fully tested designs.

-

Integration with Internet of Things (IoT) and Smart Devices

The integration of PCBs into Internet of Things (IoT) devices is one of the most transformative changes in the electronics industry. IoT devices rely on compact, low-power PCBs to connect to the internet and interact with other devices. As IoT applications continue to grow, PCB designers will need to account for wireless communication, low-power performance, and secure data transfer in their designs. CAD Drawing services can be utilized to help ensure that these designs are optimized for low-power consumption and connectivity.

CAD software will increasingly offer features that support these IoT-specific requirements, such as optimized routing for antenna designs and low-noise performance simulations.

-

Sustainability and Green PCB Design

As environmental concerns continue to rise, the demand for sustainable and eco-friendly PCB designs will grow. Designers will increasingly look for ways to minimize waste, reduce energy consumption, and use recyclable materials in their designs. 3D CAD will play an important role in helping companies meet sustainability goals by providing expert guidance on eco-friendly materials and efficient design techniques.

The Impact of 5G and High-Speed Data

The rollout of 5G technology will have a profound impact on PCB design in 2025. As 5G networks require faster data transmission and more efficient connectivity, the demand for high-speed PCBs will increase. Designers will need to consider factors such as signal integrity, power delivery, and heat dissipation in their PCB designs to meet the demands of 5G and beyond. 3D CAD will be essential in designing these high-performance boards, helping engineers to simulate and test the boards' performance under various conditions.

Conclusion

The future of PCB design in the USA is bright, with innovations in CAD technology playing a crucial role in shaping the landscape. As the demand for smaller, faster, and more reliable electronics continues to grow, designers will rely on increasingly sophisticated CAD tools to meet these challenges.

From advanced materials to AI-powered automation, the trends emerging in 2025 promise to push the boundaries of what is possible in PCB design. 3D CAD will remain vital in assisting businesses with complex designs, helping them bring innovative and high-quality products to market faster. By staying informed about these trends and embracing new technologies, PCB designers can ensure they are well-positioned to thrive in the evolving electronics market. The future of PCB design is not just about improving existing processes, but about driving innovation and opening up new possibilities for the world of electronics.

What's Your Reaction?